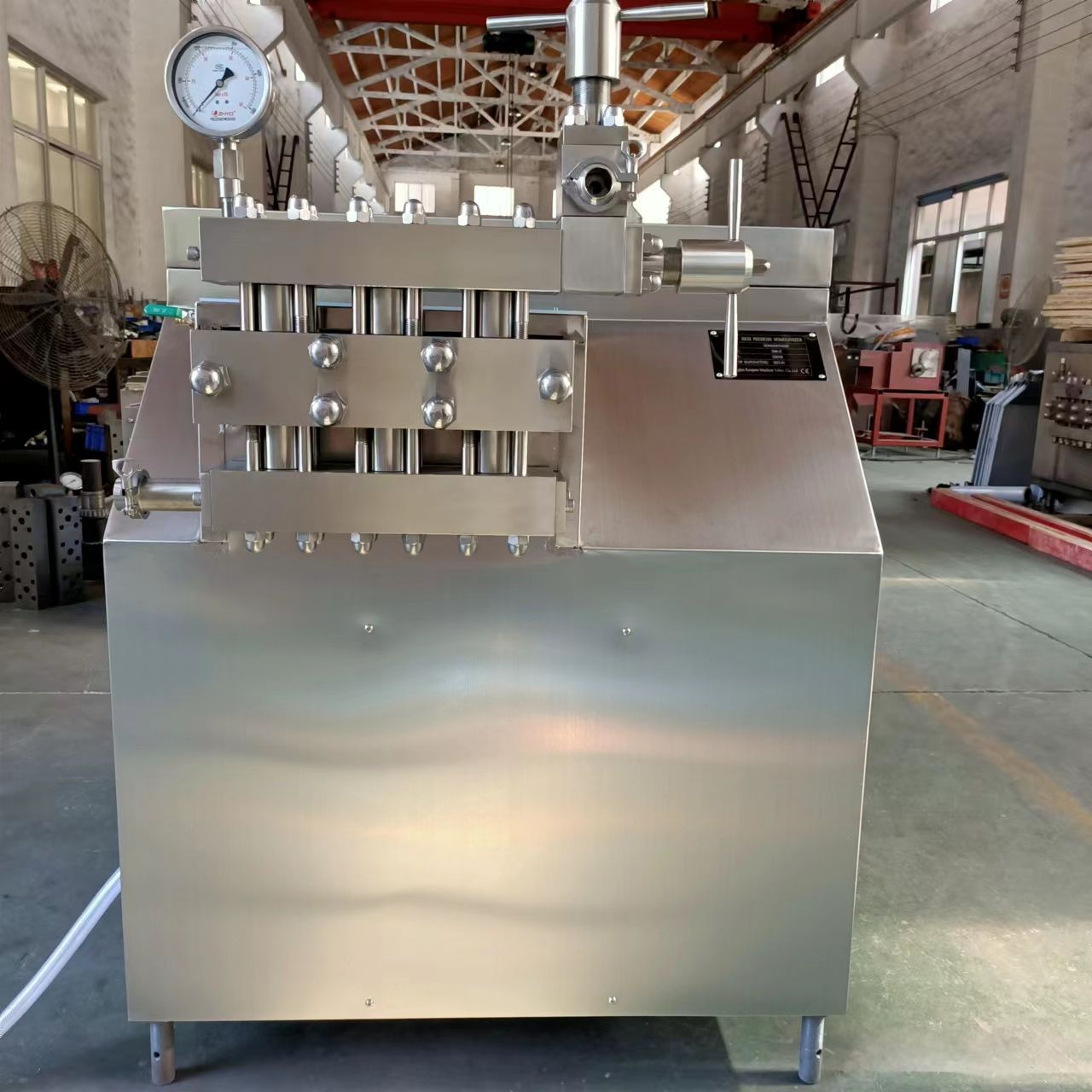

3000L and 5000L High-Pressure Homogenizers for Dairy Processing Lines

$8,010.00

Description

Introducing our 3000L and 5000L High Pressure Homogenizers, designed specifically for milk production lines. These machines ensure uniform texture and optimal shelf life, enhancing product quality. Upgrade your dairy processing today for smoother, tastier results! Don’t miss out—boost your production efficiency now!

SKU

9797302617412

Category Chemical Equipment

Tags Chemical Drying Equipment, Chemical Equipment Machinery, Chemical Granulators, Chemical Homogenizer, China Mixing, Cosmetics Homogenizer, Homogenizer Milk, Homogenizer Mixing, Mixing Equipment, Mixing Machinery, Powder Milk, Tank Homogenizer

Brand: Shanghai Kaiquan Machine Valve Co., Ltd.

Send Inquiry