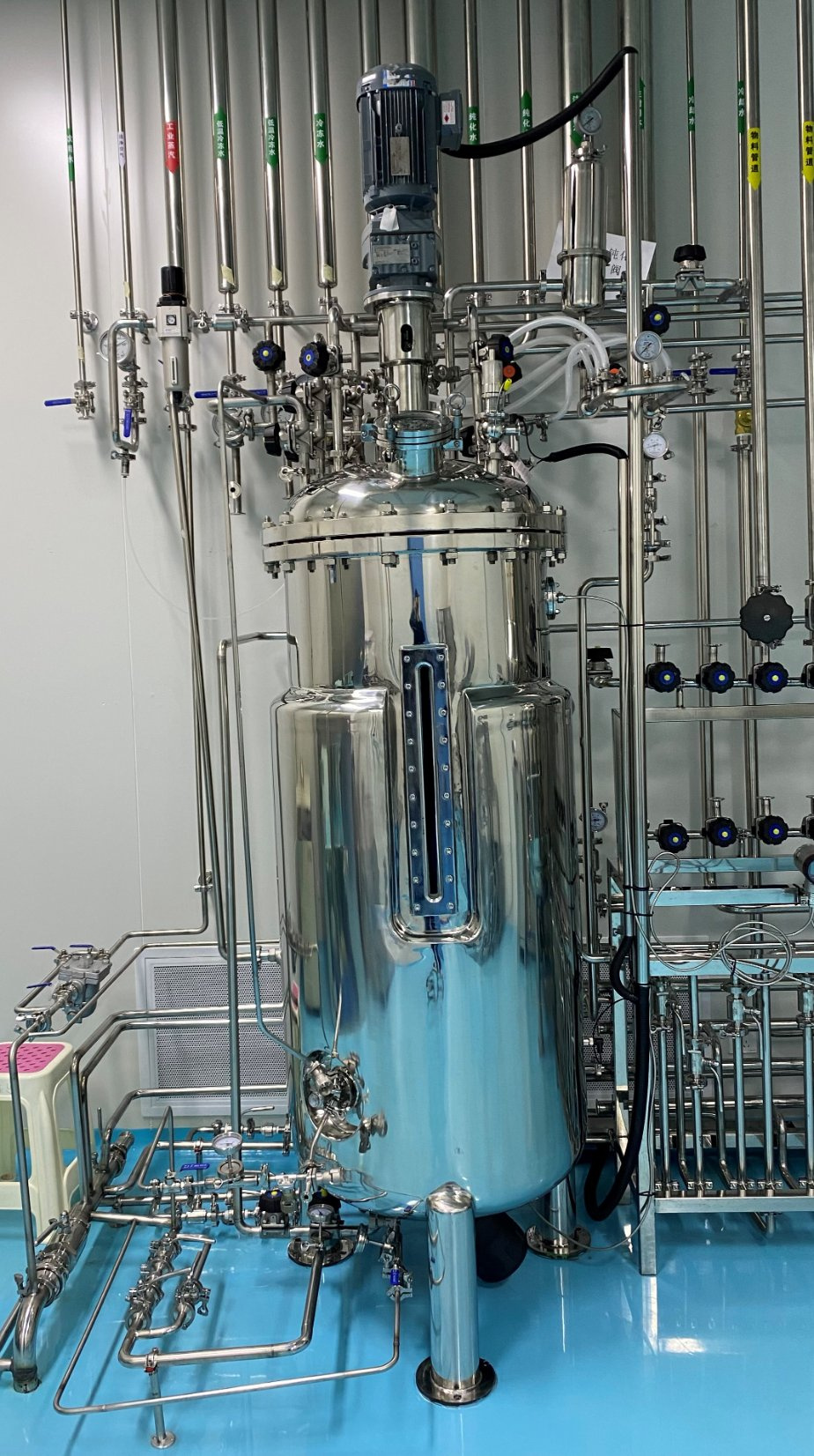

Tank Vacuum Emulsification Process for Creams and Lotions

$1,010.00

Description

Introducing our advanced Tank Vacuum Emulsifying Machine, designed to create silky creams and luxurious lotions effortlessly. With precise temperature control and powerful mixing capabilities, achieve perfect emulsions every time. Elevate your formulations and boost your production efficiency. Don’t miss out—get yours today and transform your skincare line!

SKU

0567625677288

Category Mixing equipment

Tags Blending Tank Mixing Mixer, China Mixing, China Tank, High Shear Emulsifier, Inline Emulsification Machine, Mixing Equipment, Mixing Machinery, Pressure Mixing Tank, Stainless Mixing Tank, Steel Mixing Tank, Tank Trends, Top 10 Tank, Used Mixing Tank, Vacuum Emulsifying Mixer

Brand: Zhejiang Jhen Ten Machinery Co., Ltd.

Send Inquiry