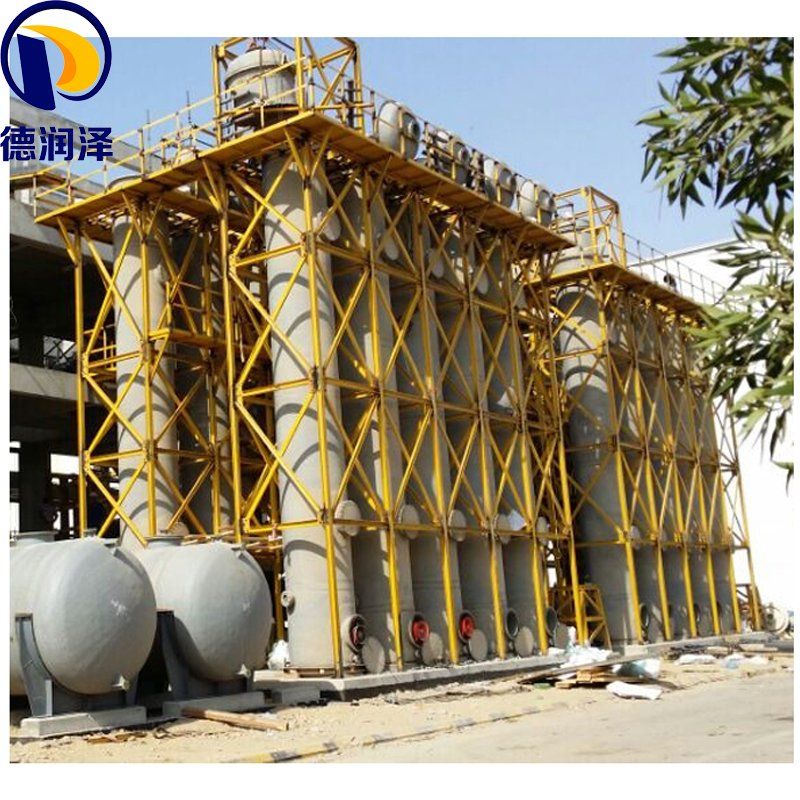

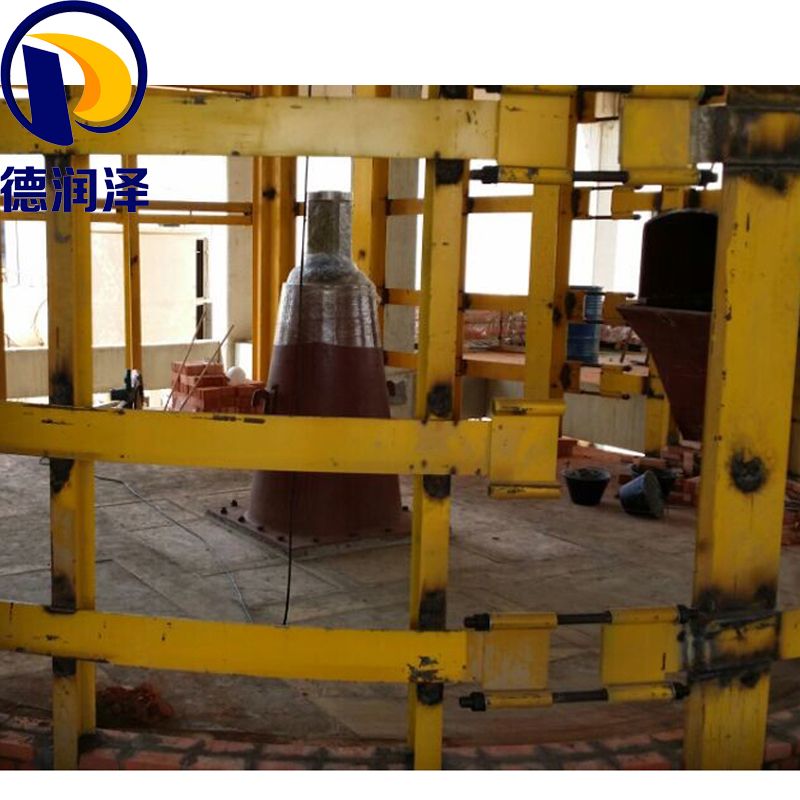

Mannheim Furnace Technology for Sodium/Potassium Sulfate Production Plant

$800,010.00

Description

Discover our state-of-the-art Mannheim Furnace Plant designed for efficient sodium/potassium sulfate production. This cutting-edge technology ensures high yield, reliability, and sustainability. Elevate your operations today—order now and transform your production!

SKU

9216440093547

Category Chemical Equipment

Tags Cement Plant, Chemical Drying Equipment, Chemical Equipment Machinery, Chemical Granulators, China Plant, Fertilizer Plant Equipment, Fertilizer Production Line, Fertilizer Production Plant, Plant Equipment, Plant Food Fertilizer, Production Line, Production Line Plant, Production Line Trends

Brand: Hebei Derunze Chemical Equipment Co., Ltd

Send Inquiry