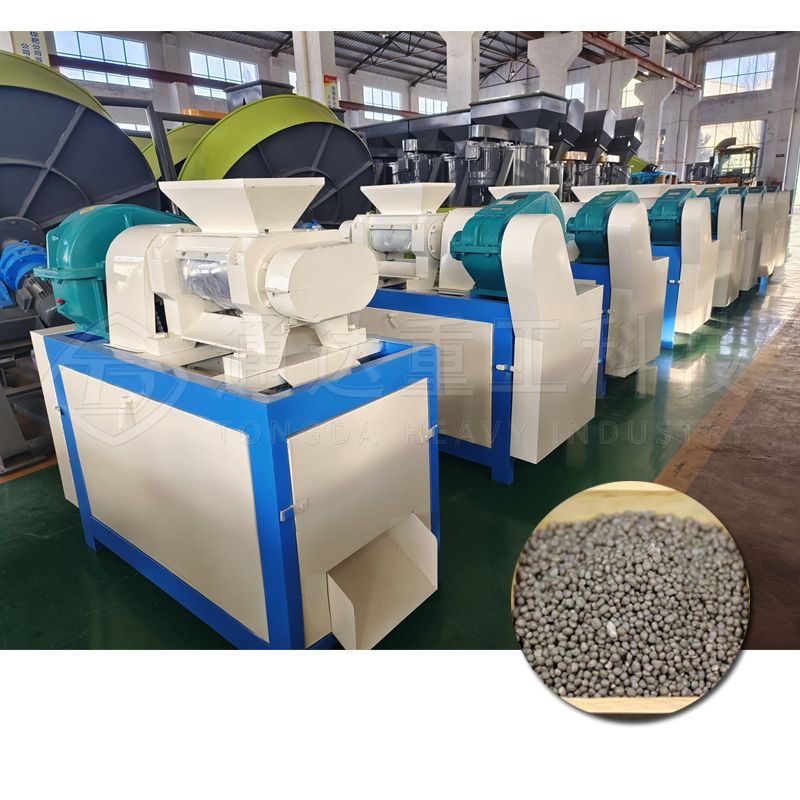

Granulation Equipment for NPK Compound Fertilizer Using Granule Double Roller Extrusion

$2,810.00

Description

Introducing our Granule Double Roller Extrusion NPK Compound Fertilizer Granulation Equipment, designed for efficient and high-quality fertilizer production. Maximize your yield with customizable settings and robust construction. Elevate your farming game—purchase now for sustainable growth!

SKU

6992805440127

Category Chemical Equipment

Tags Chemical Drying Equipment, Chemical Equipment Machinery, Chemical Machine Parts, China Machine, Double Machine, Extrusion Machine, Feed Pellet Granulator Machine, Machine Trends, Oscillating Granulator, Pellet Granulator, Pellet Granulator Machine, Pharmaceutical Granulator, Press Machine, Roller Granulator Machine, Rotary Drum Granulator, Top 10 Machine, Wood Pellet Granulator Machine

Brand: Henan Tongda Heavy Industry Science And Technology Co., Ltd.

Send Inquiry