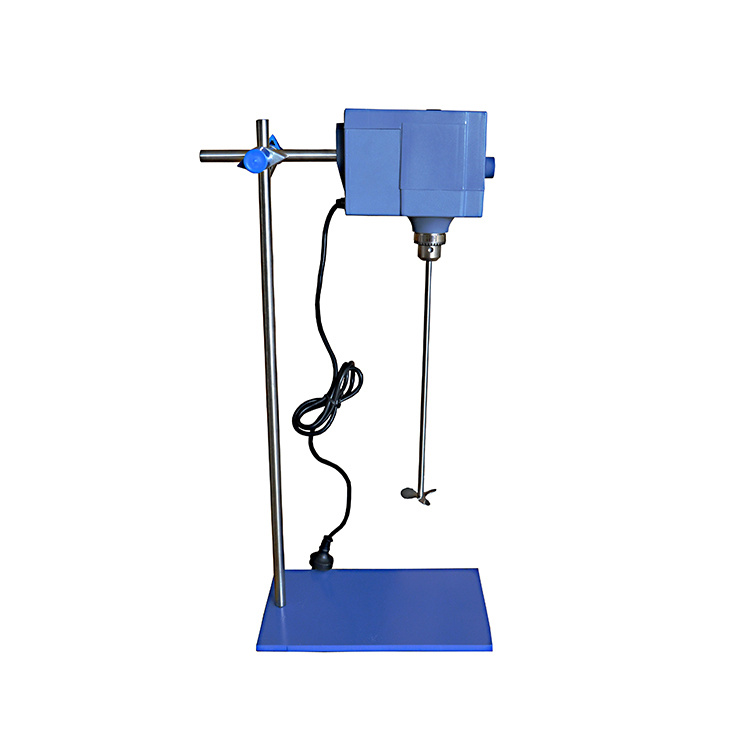

30,000L High-Pressure Chemical Reactor/Autoclave/Mixer Agitator for Phenolic, Urea Formaldehyde, Polyester, and Rosin Resins

$5,010.00

Description

Introducing our 30000L High Pressure Chemical Reactor, designed for optimal mixing and polymerization of Phenolic, Urea Formaldehyde, Polyester, and Rosin Resins. Engineered for durability and efficiency, it ensures superior performance under high pressure. Upgrade your manufacturing process today! Don’t miss out—invest in quality and reliability!

SKU

6086439105581

Category Chemical Equipment

Tags Batch Chemical Reactor, Blender Mixer, Chemical Drying Equipment, Chemical Equipment Machinery, Chemical Granulators, Concrete Mixer Machine, Glass Lined Reactor, High Speed Mixing Mixer, Mixing Equipment, Mixing Machinery, Mixing Mixer, Mixing Tank Machinery, Powder Mixer Mixing Machine, Powder Mixer Mixing Machinery, Stainless Steel Chemical Reactor

Brand: Foshan JCT Machinery Co., Ltd.

Send Inquiry