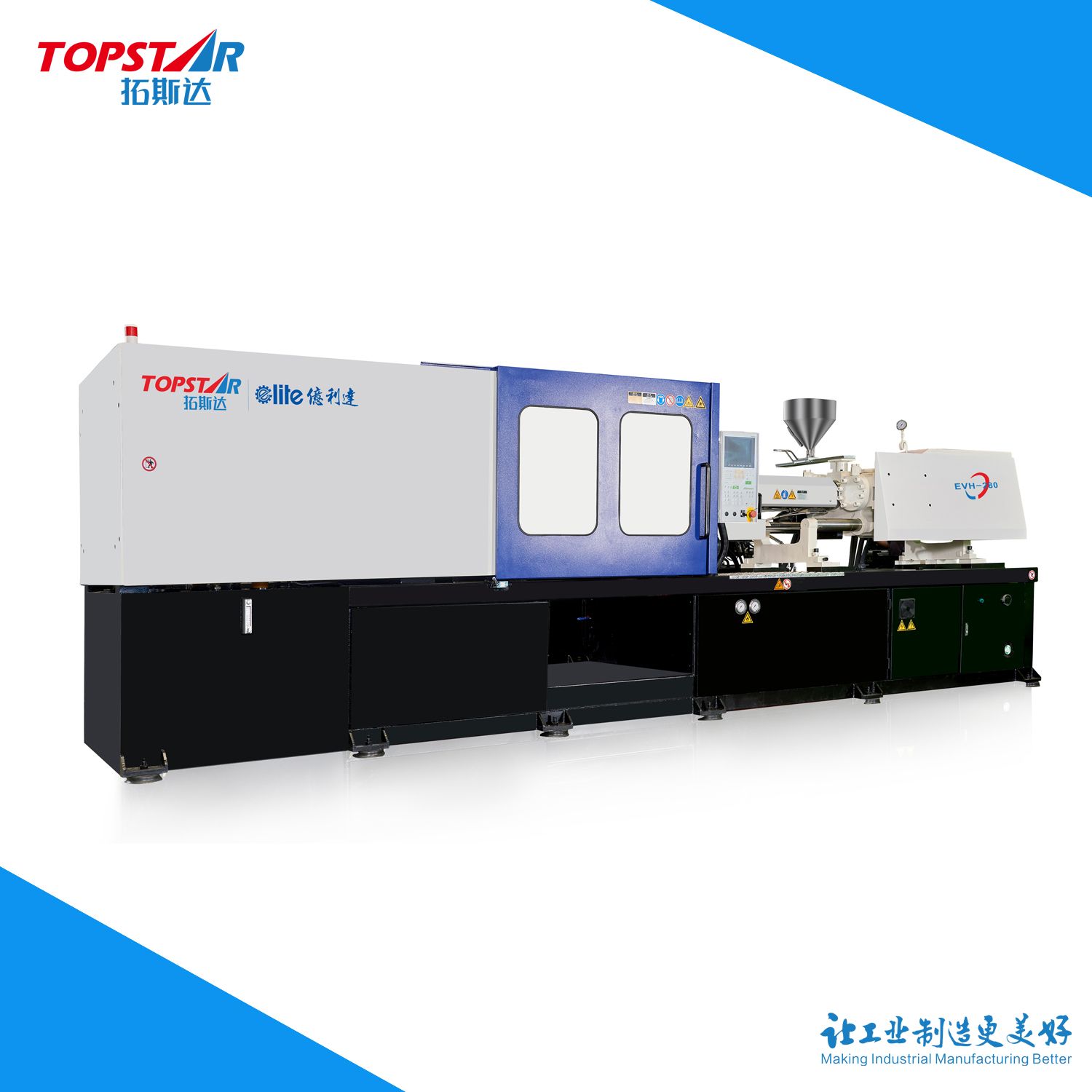

Automotive Door Injection Molding Machine

$25,010.00

Description

Introducing our Auto Car Door Plant Injection Molding Machine, designed for precision and efficiency in automotive manufacturing. With advanced technology, it ensures high-quality door components while minimizing waste. Upgrade your production line today and boost your output! Don’t miss out—invest in innovation now!

SKU

3852429052018

Category Plastic Machinery

Tags Automatic Plastic Injection Molding Machine, Blow Molding Machine, Blowing Mould, High-Speed Thin-Wall Injection Molding Machine, Hybrid Injection Molding Machine, Injection Molding Machine For Plastic, Molding Machine, New Plastic Injection Molding Machine, Other Plastic Machinery, PET Preform Injection Molding Machine, Plastic Injection Machine, Plastic Injection Molding Machine Parts, Plastic Machine, Plastic Parts, Plastic Product Injection Molding Machine

Brand: Guangdong Topstar Technology Co., Ltd.

Send Inquiry