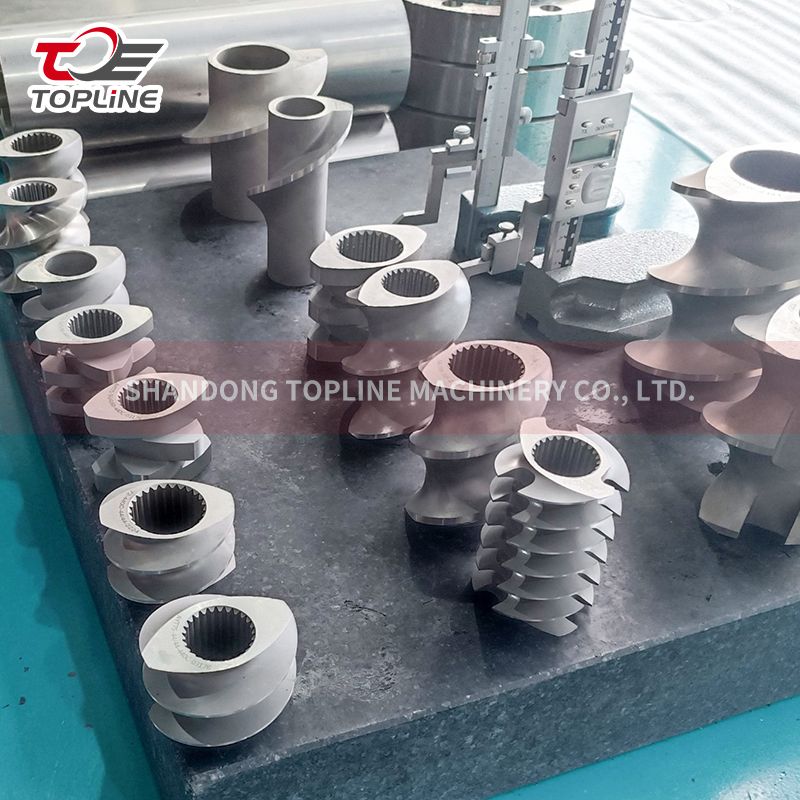

Twin Screw Compounding Extruder Screw Element for Extruder Barrel

$22.00

Description

Enhance your production efficiency with our Twin Screw Compounding Extruder Screw Element. Designed for superior mixing and compounding, this high-quality component ensures optimal performance in your extrusion processes. Upgrade your equipment today for unmatched results!

SKU

0436308641977

Category Food & Beverage Equipment

Tags Beverage Cereal Production Line, Biscuit Production Line, Chocolate Production Line, Cooking Baking Equipment, Dairy Processing Machinery, Extruder Screw Barrel, Extruder Twin Screw Barrel, Food, Machine Screw, Potato Chip Production Line, Screw Extruder, Screw Machinery, Single Screw Barrel Extruder, Twin Double Screw Extruder, Twin Screw For Extruder, Wood Screw

Brand: Shandong Topline Machinery Co., Ltd.

Send Inquiry