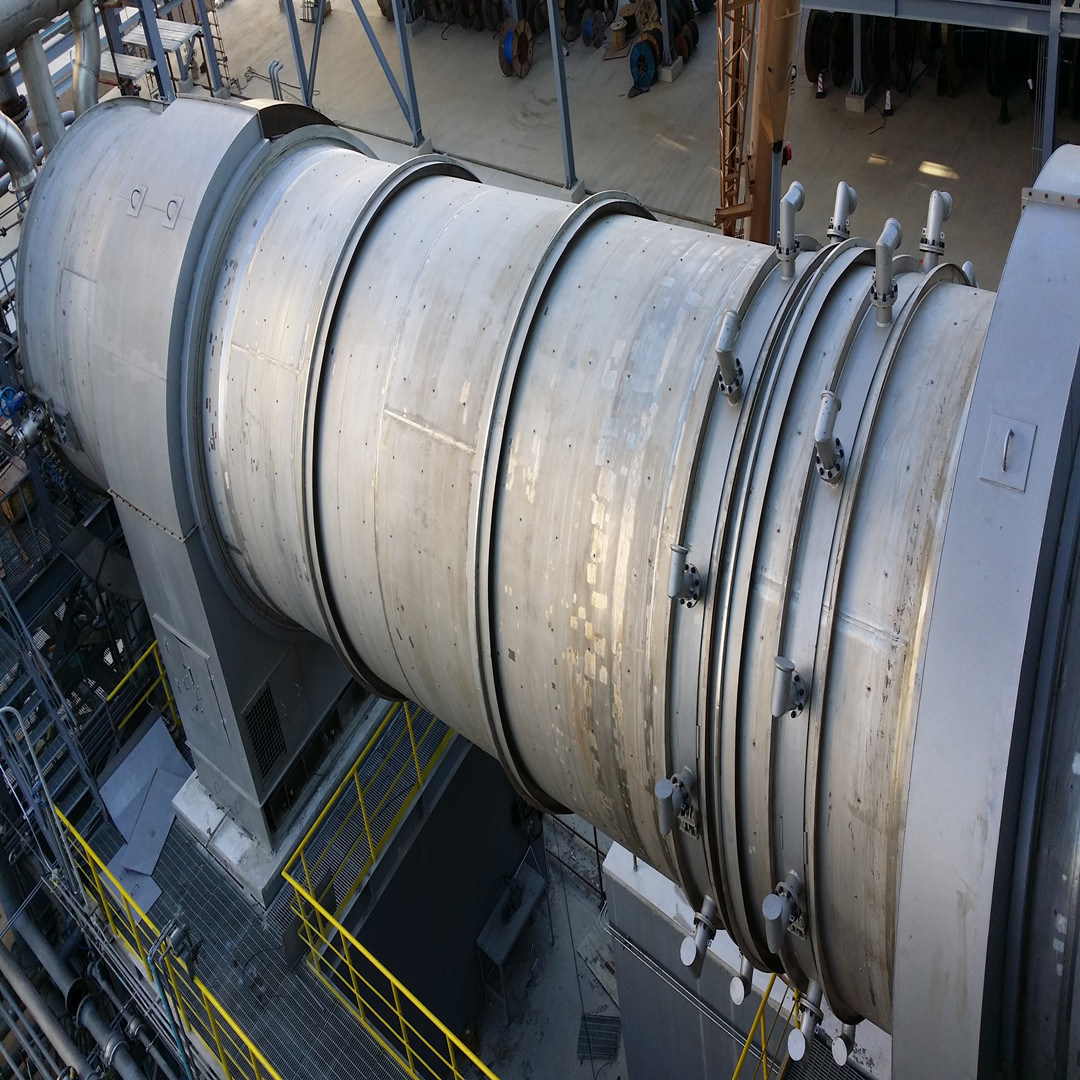

Calcium Chloride Manufacturing Process and Drying Equipment

$380,010.00

Description

Discover our state-of-the-art Calcium Chloride Production Process and Drying Equipment! Designed for efficiency and quality, it maximizes output while minimizing waste. Elevate your operations today—invest in our innovative solutions and take your production to the next level!

SKU

9309898578708

Category Chemical Equipment

Tags Calcium Food, Calcium Line, Chemical Equipment Machinery, Chemical Granulators, Chemical Machine Parts, Chemical Spray Dryer, Equipment Part, Fluid Bed Dryer, Kitchen Equipment, Polyvinyl Chloride Granule, Polyvinyl Chloride Pellet, Polyvinyl Chloride Plate, Process Equipment, Production Equipment, Vacuum Drying Equipment

Brand: Banghua International Granulation Engineering Co., Ltd.

Send Inquiry