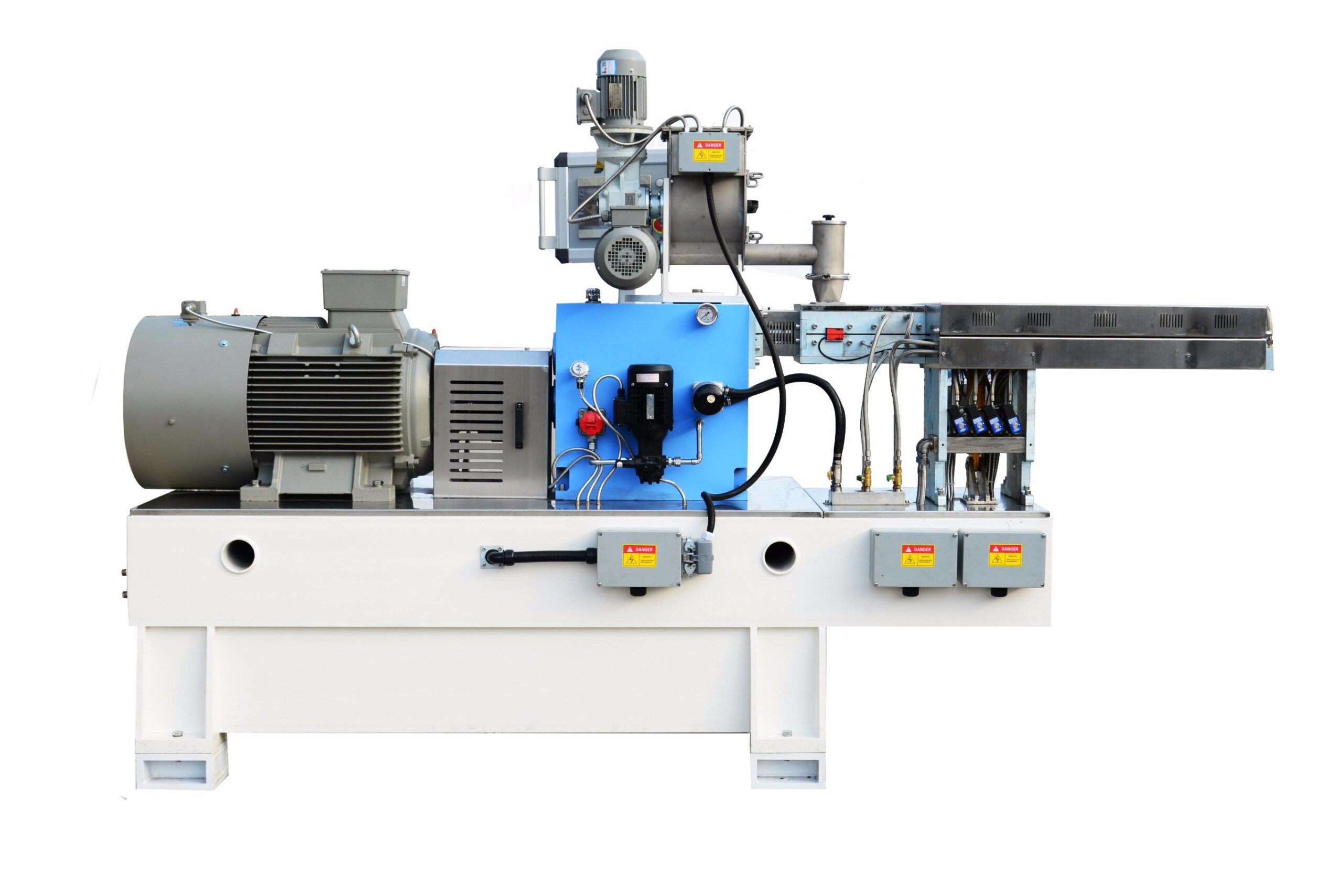

PE/PP with Glass Fiber Granule Extrusion Production Line

$50,010.00

Description

Introducing our PE/PP + Glass Fiber Granule Extrusion Production Line, designed for high efficiency and durability. Perfect for producing premium quality composite granules, this state-of-the-art equipment ensures consistent output and enhances material strength. Don’t miss the chance to elevate your production capabilities—invest in our line today!

SKU

6634759612556

Category Plastic Machinery

Tags Conical Twin Screw Extruder, Extruder Extrusion, Extruder Machinery, Plastic Extruder Line, Plastic Extruder Machinery, Plastic Extruder Production, Plastic Extruder Production Line, Plastic Extrusion Machine Extruder, Plastic Pipe Machinery, Plastic Production Line, Plastic Rolling Machinery, Screw Extruder, Screw Extruder Machine, Single Screw Extruder, Twin Screw Extruder

Brand: Nanjing Kairong Machinery Tech. Co., Ltd.

Send Inquiry