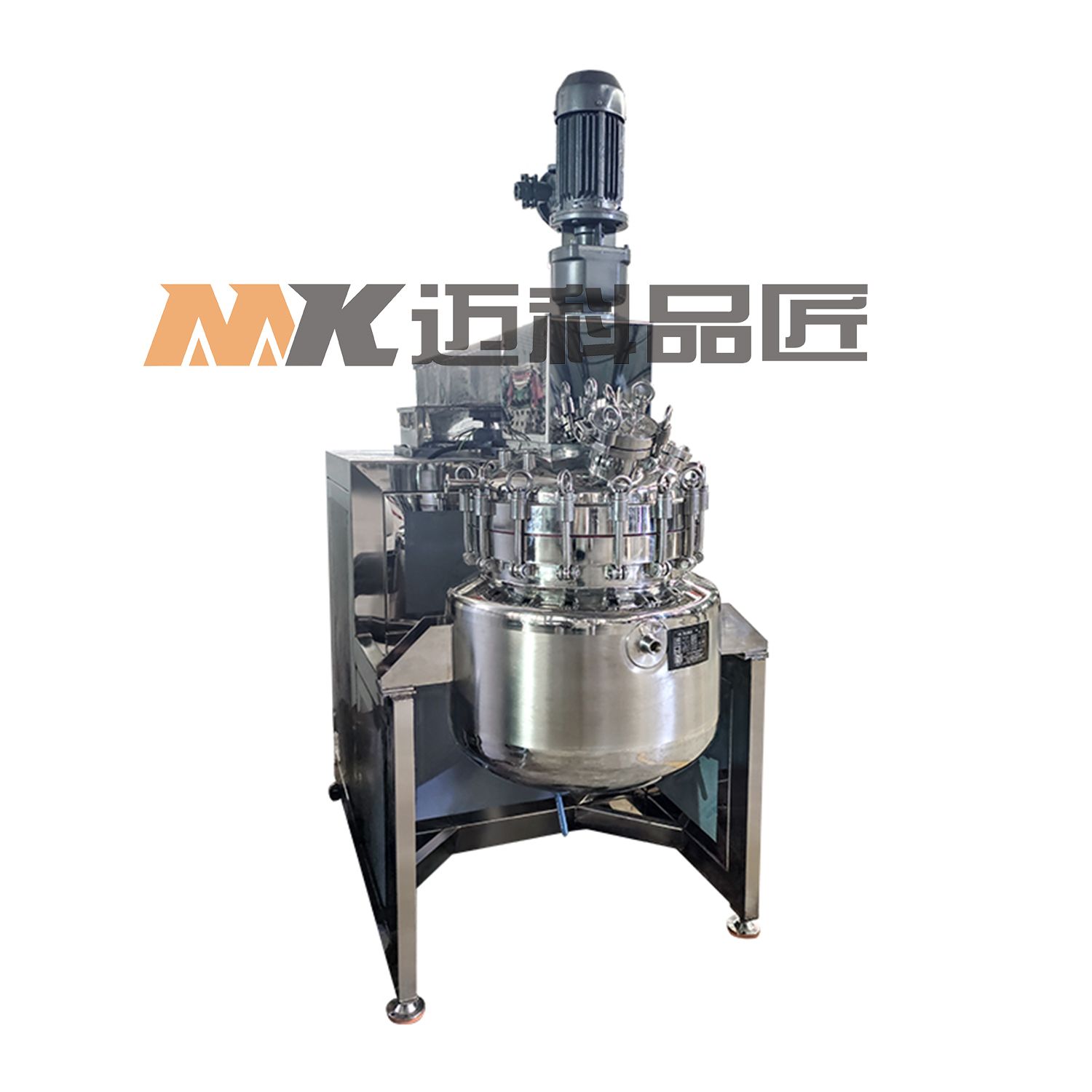

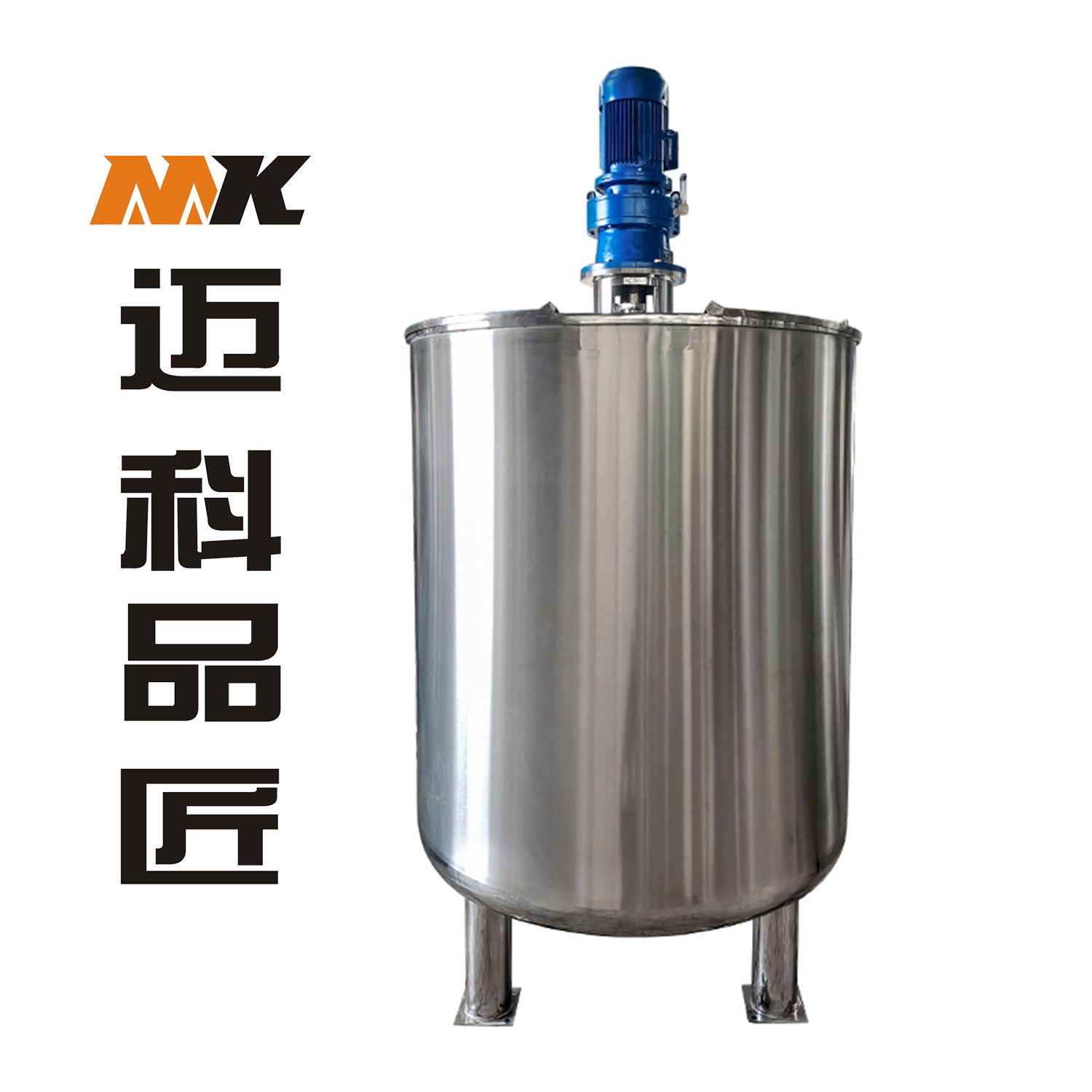

100L High-Pressure Stainless Steel Steam Heating Jacketed Reactor for Cosmetics Vacuum Homogenizer Mixer Emulsifier

$9,910.00

Description

Introducing our 100L Stainless Steel Steam Heating Jacketed High Pressure Reactor, designed for cosmetics manufacturing. This vacuum homogenizer mixer emulsifier ensures superior blending and temperature control, producing high-quality formulations. Elevate your production process—order now!

SKU

7867348255230

Category Chemical Equipment

Tags Batch Chemical Reactor, Chemical Drying Equipment, Chemical Equipment Machinery, Chemical Granulators, Chemical Tank, China Tank, Continuous Flow Reactor, Glass Lined Reactor, ISO Tank, Reactor Chemical, Reactor Tank, Stainless Reactor, Stainless Steel Reactor, Stainless Steel Tank, Steel Reactor, Tank Trends, Top 10 Tank

Brand: Guangzhou Maike Machinery Co., Ltd

Send Inquiry