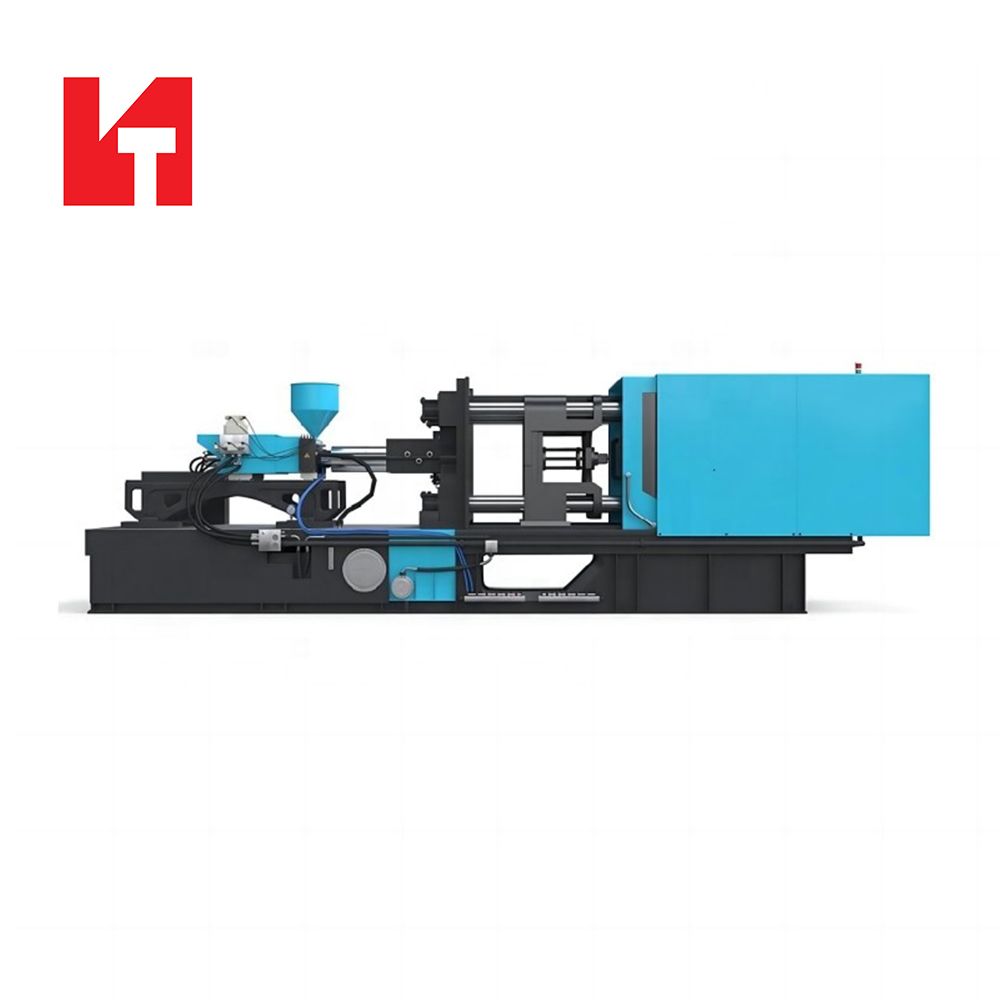

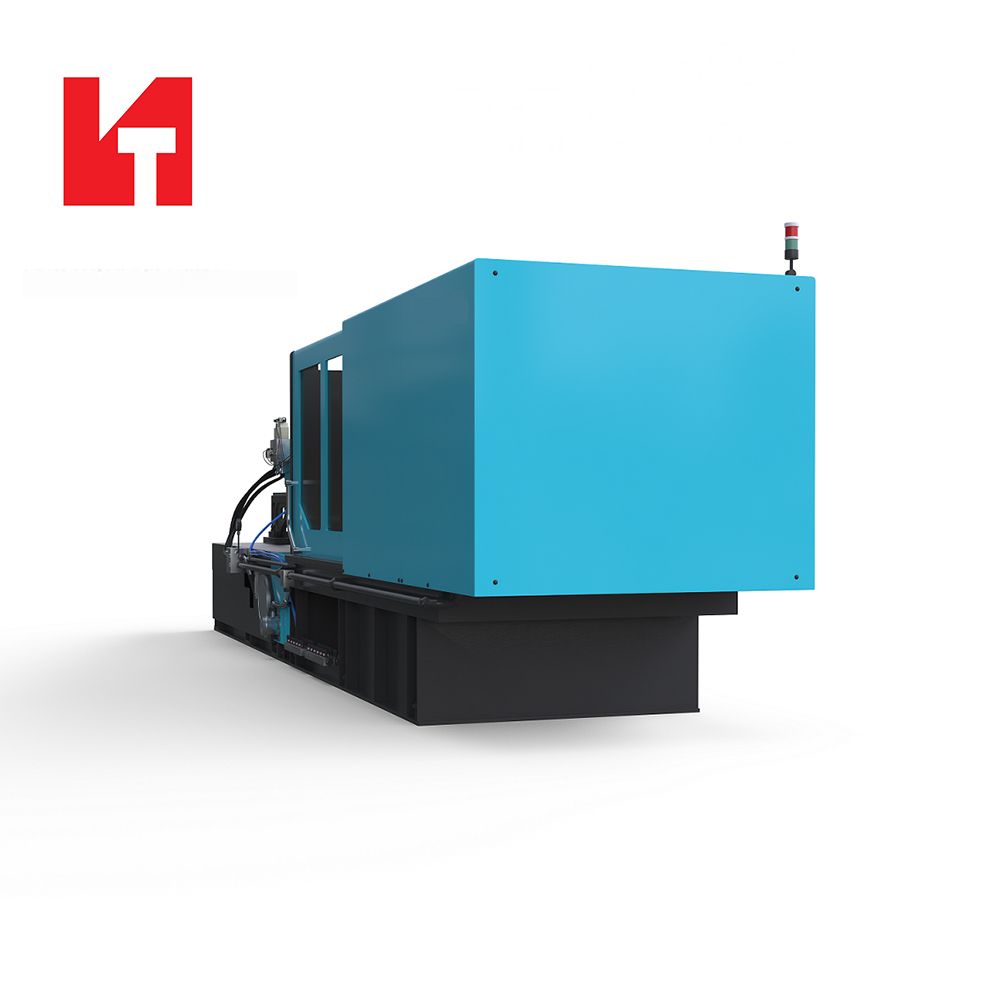

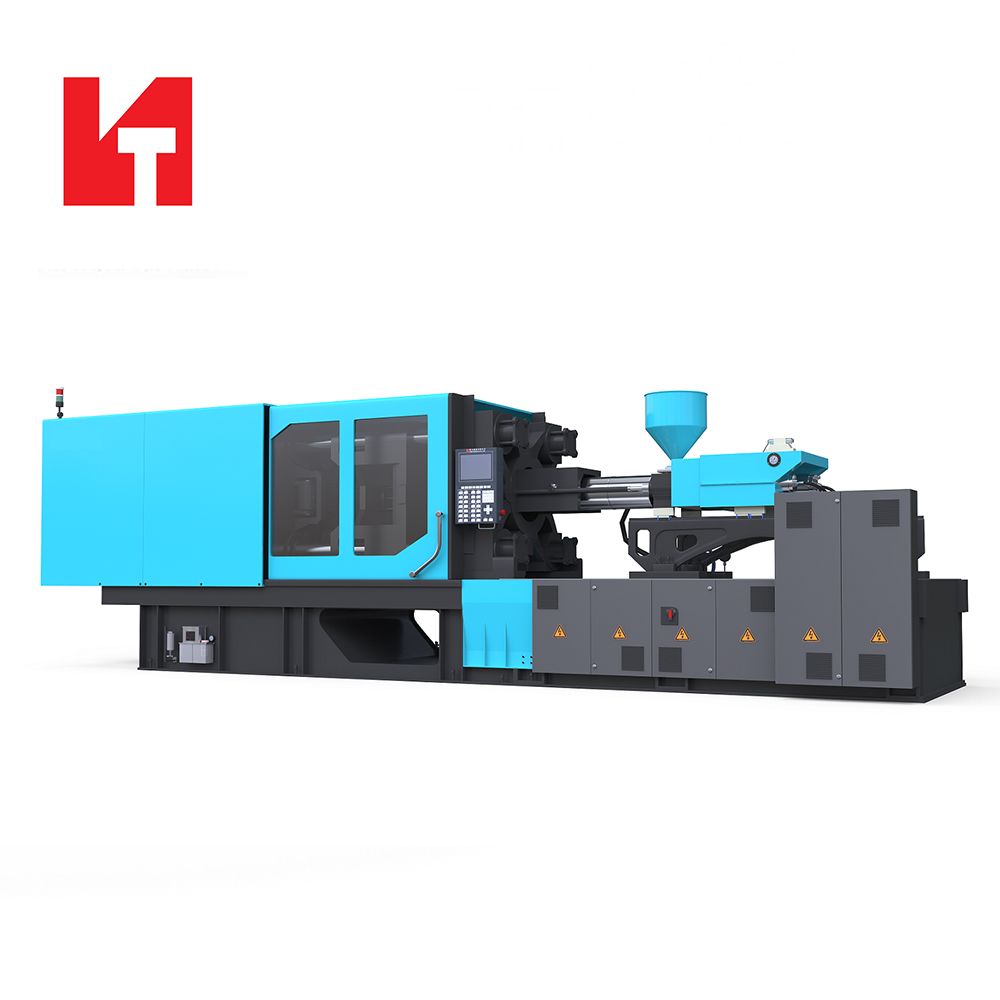

330-Ton Infrared Heated Servo Hydraulic Plastic Injection Molding Machine

$42,510.00

Description

Introducing our 330 Ton Infrared Heating Servo Hydraulic Plastic Injection Molding Machine! This advanced equipment combines precision and efficiency, ensuring high-quality plastic production. Boost your manufacturing capabilities and reduce energy costs with our cutting-edge technology. Don’t miss out—transform your operations today!

SKU

4244541226633

Category Plastic Machinery

Tags All-Electric Injection Molding Machine, Blow Molding Machine, Blowing Mould, Custom Plastic Injection Molding, Custom Plastic Injection Molding Parts, Horizontal Injection Molding Machine, Machines Injection, Other Plastic Machinery, PET Preform Injection Molding Machine, Plastic Injection Machine, Plastic Injection Molding, Plastic Injection Molding Products, Plastic Injection Product, Plastic Molding Injection Machinery, Plastic Product Injection Molding Machine

Brand: Fuzhou Leantall Technology Co., Ltd

Send Inquiry