AE Type Acid and Alkali Resistant Enamel / Glass-Lined Reactor

$1,010.00

Description

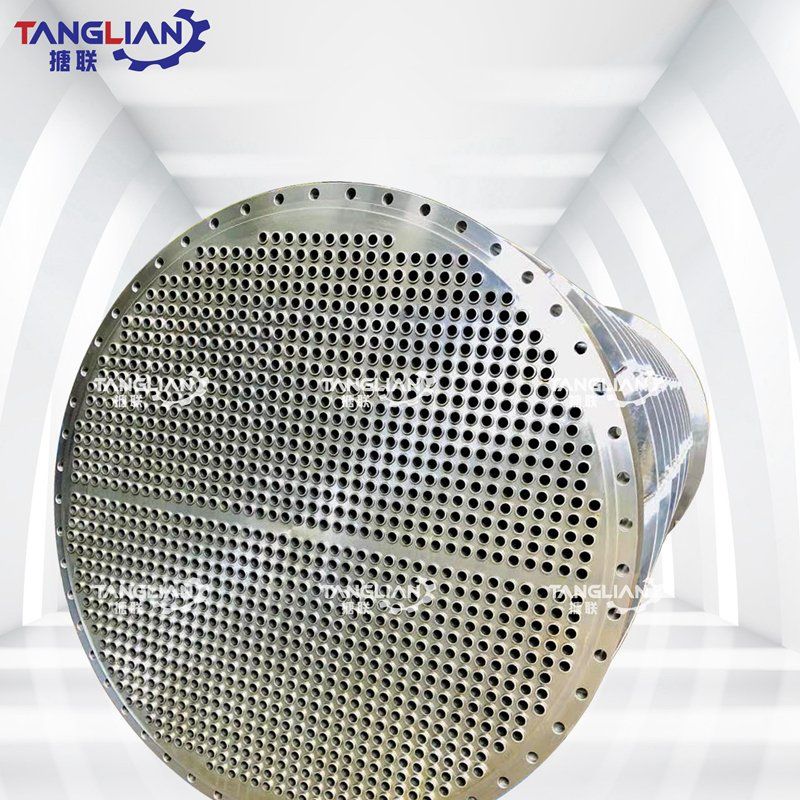

Introducing our AE Type Acid and Alkali Resistant Enamel/Glass Lined Reactor, designed for superior durability and protection against corrosive chemicals. Ideal for various industrial applications, it ensures optimal performance and longevity. Elevate your operations today—invest in reliability and efficiency! Don’t miss out—order now!

SKU

8507111943135

Category Chemical Equipment

Tags Chemical Drying Equipment, Chemical Equipment Machinery, Chemical Granulators, China Tank, Cooling Tank, High-Temperature Vessel, ISO Tank, Low-Pressure Vessel, Oil Reactor, Reactor Tank, Reactor Tank Equipment, Stainless Reactor, Stainless Steel Tank, Steel Reactor, Storage Vessel, Tank Trends, Top 10 Tank

Brand: Shandong Tanglian Chemical Equipment Co., Ltd.

Send Inquiry