Agitated Nutsche Filter Dryer for the Chemical Industry in Pharmaceutical Labs

$9,010.00

Description

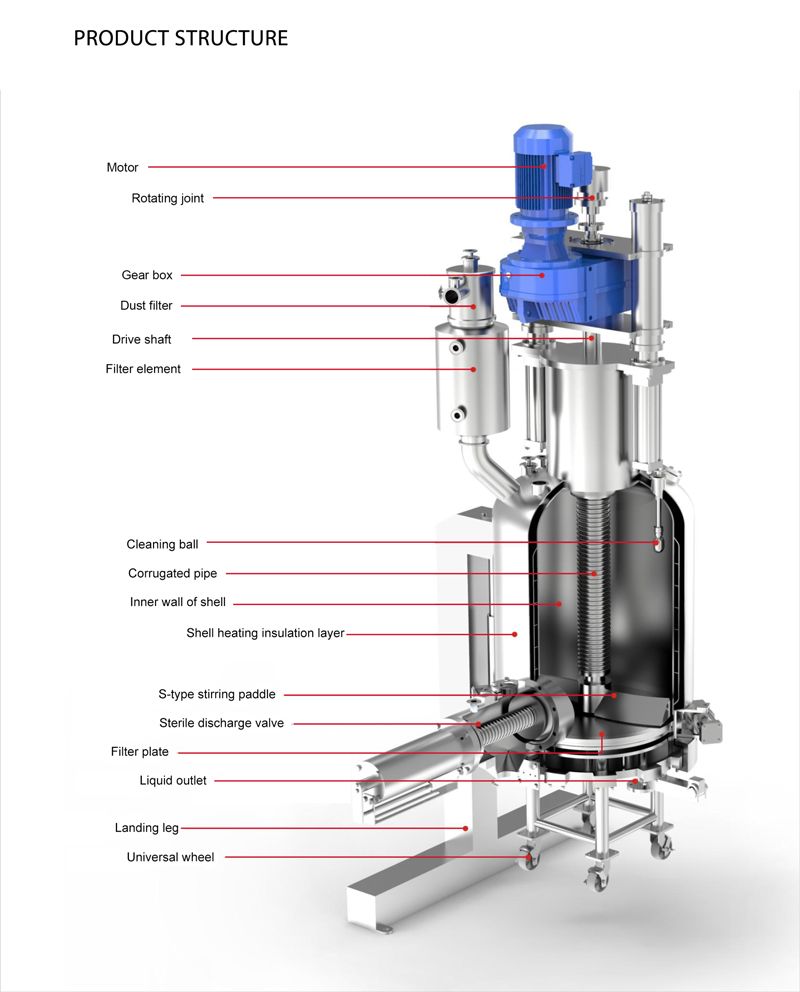

Introducing our Agitated Nutsche Filter Dryer, designed for the chemicals industry and pharmaceutical labs. This advanced equipment ensures efficient solid-liquid separation and optimal drying. Enhance your production process with superior performance and reliability. Don’t miss out—invest in quality today!

SKU

4396521054753

Category Chemical Equipment

Tags Chemical Equipment Machinery, Chemical Granulators, Chemical Machine Parts, Chemical Spray Dryer, Corn Dryer Machine, Dryer Oven Machine, Drying Equipment, Drying Machinery, Freeze Drying Dryer Machine Equipment, High Drying Capacity Dryer, Industrial Chemical Dryer, Industrial Washing Machine, Mineral Dryer Machine, Plastic Washing Machine, Vacuum Drying Equipment

Brand: Jiangsu Xingxing Drying Equipment Co., Ltd.

Send Inquiry