Automatic Cleaning in Place (CIP) Systems for Food Processing Facilities

$8,010.00

Description

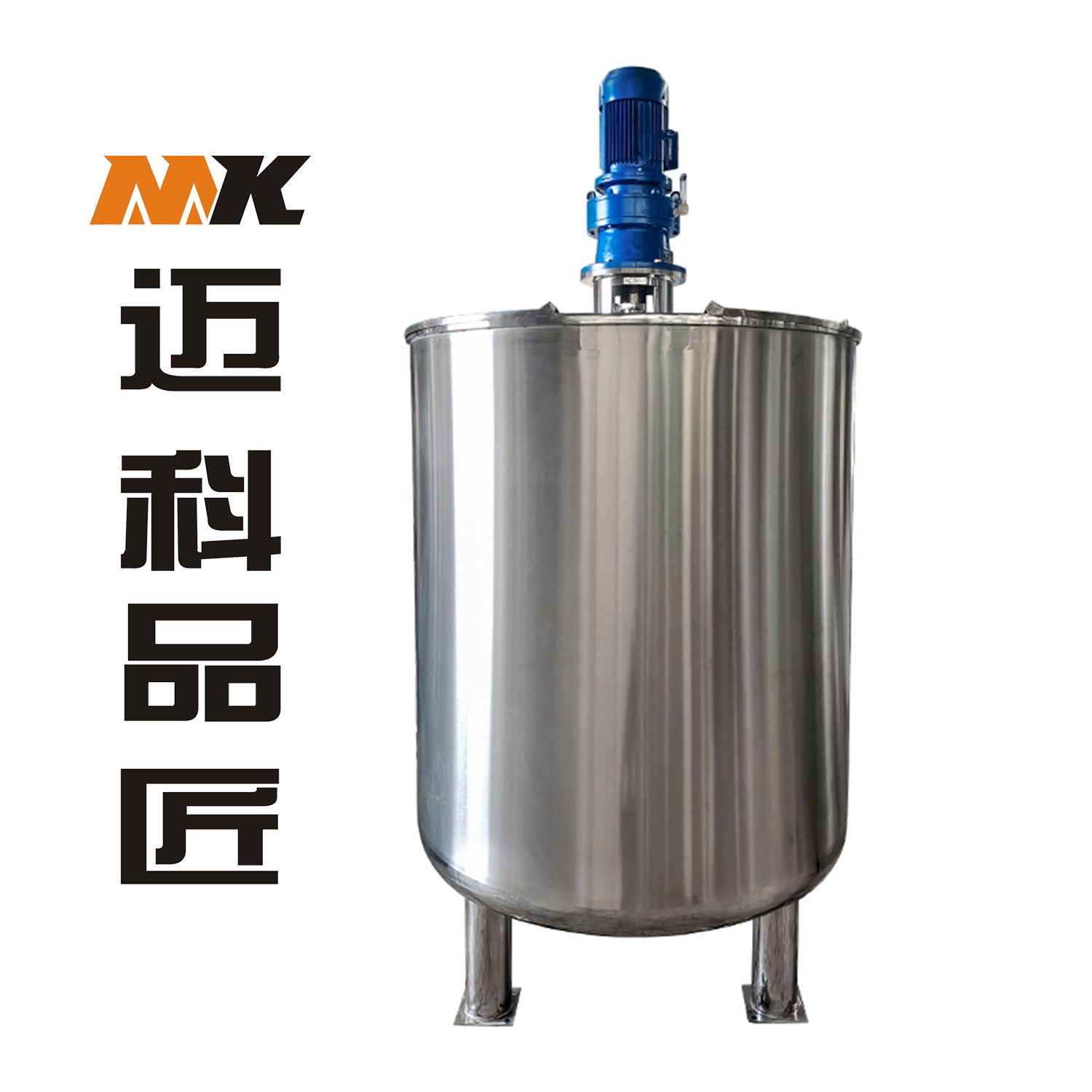

Introducing our Automatic Clean in Place (CIP) System, designed specifically for food plants. This innovative Cleaning Vessel System ensures thorough sanitation with minimal downtime, enhancing efficiency and compliance. Elevate your hygiene standards and streamline operations—order now for a cleaner, safer production environment!

SKU

9166613956965

Category Food & Beverage Equipment

Tags Automatic Cip System, Automatic Control System, Automatic System, Beverage Concentration Equipment, Beverage Filtration Equipment, Beverage Heat Treatment Equipment, China Tank, Cip Cleaning System, Cip Tank, Customized Cleaning Tank, Filling Machine, Industry System, Packing Line, Pet Food Processing Machinery, Pipe Cleaning System

Brand: Shanghai Stable Industrial Co., Ltd.

Send Inquiry