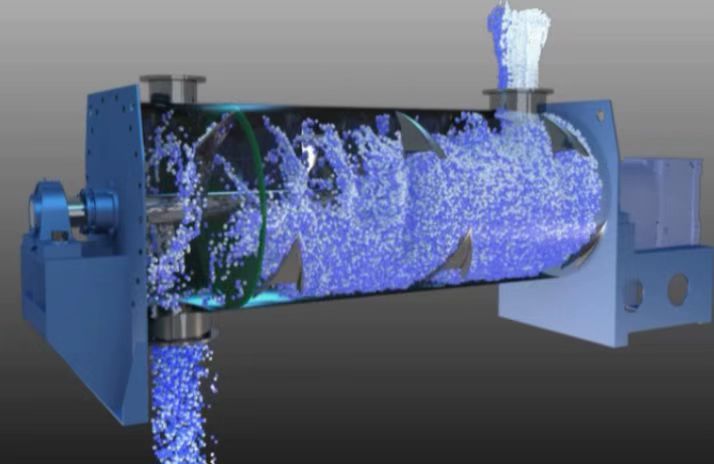

Batch Mixer vs. Continuous Mixer

$10,010.00

Description

Introducing our Batch Mixer and Continuous Mixer – the perfect duo for all your mixing needs! Achieve consistent results with our state-of-the-art technology, designed for efficiency and quality. Transform your recipes today and elevate your production. Don’t miss out—order now!

SKU

4010641971680

Category Chemical Equipment

Tags Blender Machine, Blender Mixer, Chemical Drying Equipment, Chemical Equipment Machinery, Chemical Granulators, China Mixer, Concrete Mixer Machine, Continuous Mixer, Continuous Mixing Machine, Horizontal Continuous Machine, Mixer Trends, New Continuous Mixer, Powder Continuous Machine, Top 10 Mixer

Brand: Shanghai Shengli Machinery Manufacturing Co., Ltd.

Send Inquiry