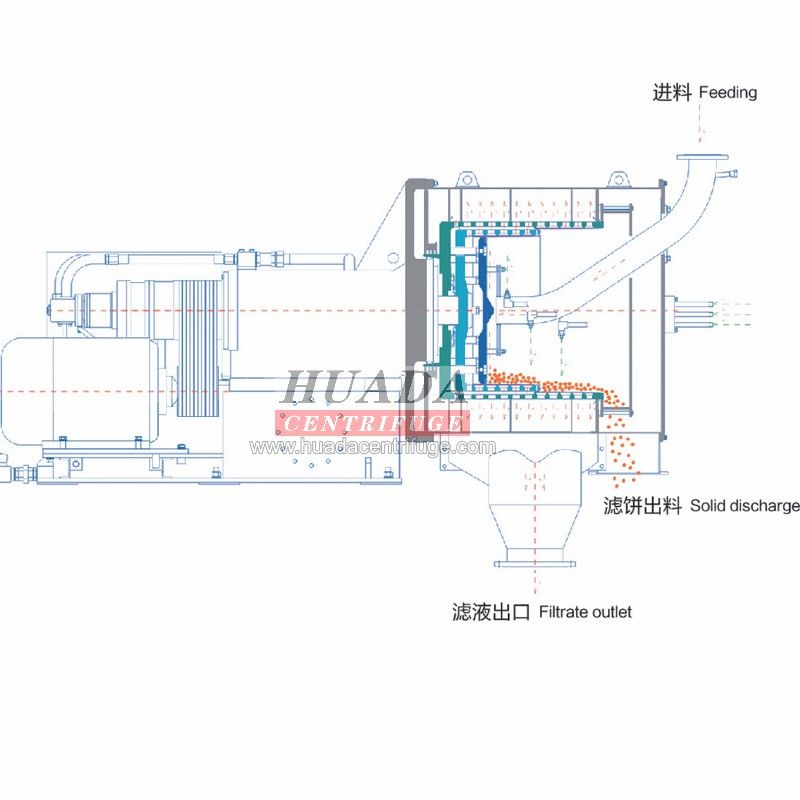

Continuous Operation of 2-Stage Pusher Centrifuge Effectively Utilized for Iron Sulphate Heptahydrate Processing

$30,010.00

Description

Introducing our Continuous Working 2-Stage Pusher Centrifuge, expertly designed for efficient separation of Iron Sulphate Heptahydrate. Achieve high purity and reduced processing times. Upgrade your operations today—don’t miss out, purchase now!

SKU

8171679833977

Category Chemical Equipment

Tags Automatic Centrifuge, Automatic Cutting Machine, Automatic Industrial Equipment, Automatic Machine, Centrifuge Industrial, Centrifuge Machines, Centrifuge Separation Equipment, Centrifuge Separator, Chemical Drying Equipment, Chemical Equipment Machinery, Chemical Granulators, Membrane Separation Equipment, Sludge Separation Equipment, Used Centrifuge, Working Machines

Brand: Jiangsu Huada Centrifuge Co., Ltd.

Send Inquiry