Continuous Operation Pusher Centrifuge for Ferrous Sulphate Applications

$30,010.00

Description

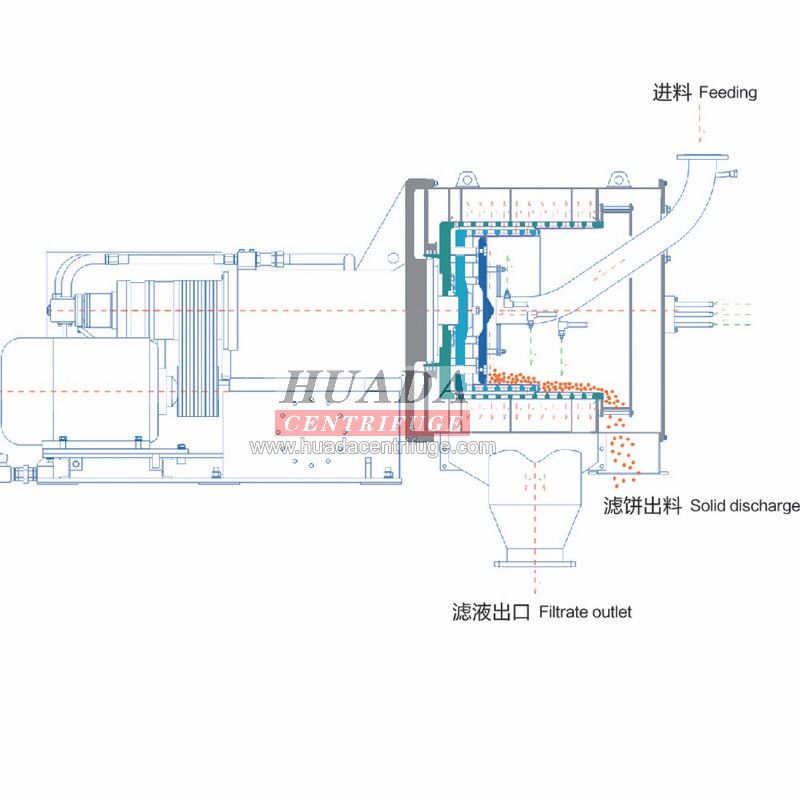

Introducing our HR Continuously Operating Pusher Centrifuge, designed specifically for efficient separation of Ferrous Sulphate. With robust performance and minimal downtime, it enhances productivity while ensuring quality. Upgrade your operations today—experience the difference! Buy now!

SKU

8390653279580

Category Chemical Equipment

Tags Automatic Centrifuge, Automatic Cutting Machine, Automatic Industrial Equipment, Automatic Machine, Centrifuge Industrial, Centrifuge Machines, Centrifuge Separator, Chemical Drying Equipment, Chemical Equipment Machinery, Chemical Machine Parts, High Shear Granulator, Industrial Washing Machine, Oscillating Granulator, Rotary Drum Granulator, Used Centrifuge

Brand: Jiangsu Huada Centrifuge Co., Ltd.

Send Inquiry