Continuous Operation Pusher Centrifuge for Hydrogen Carbonate Processing

$30,010.00

Description

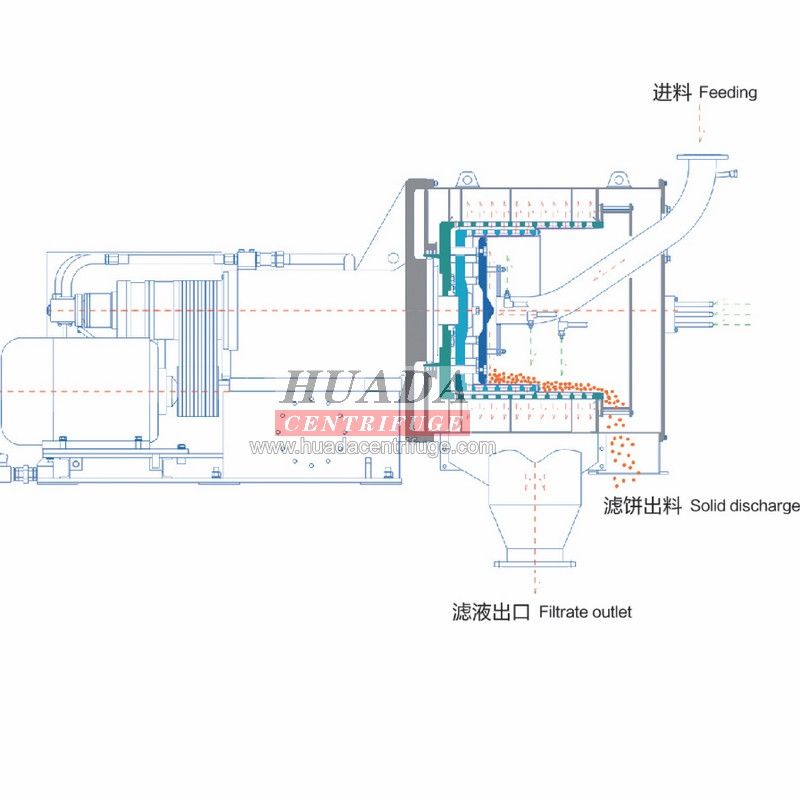

Introducing our HR Continuously Operating Pusher Centrifuge, expertly designed for efficient hydrogen carbonate separation. With advanced technology, it ensures optimal performance and reliability. Don’t miss out—elevate your operations today!

SKU

9218727110091

Category Chemical Equipment

Tags Automatic Centrifuge, Automatic Cutting Machine, Automatic Industrial Equipment, Automatic Machine, Centrifuge Industrial, Centrifuge Machines, Centrifuge Separator, Chemical Drying Equipment, Chemical Equipment Machinery, Chemical Granulators, Gold Separation Equipment, Industrial Washing Machine, Recycling Separation Equipment, Sludge Separation Equipment, Used Centrifuge

Brand: Jiangsu Huada Centrifuge Co., Ltd.

Send Inquiry