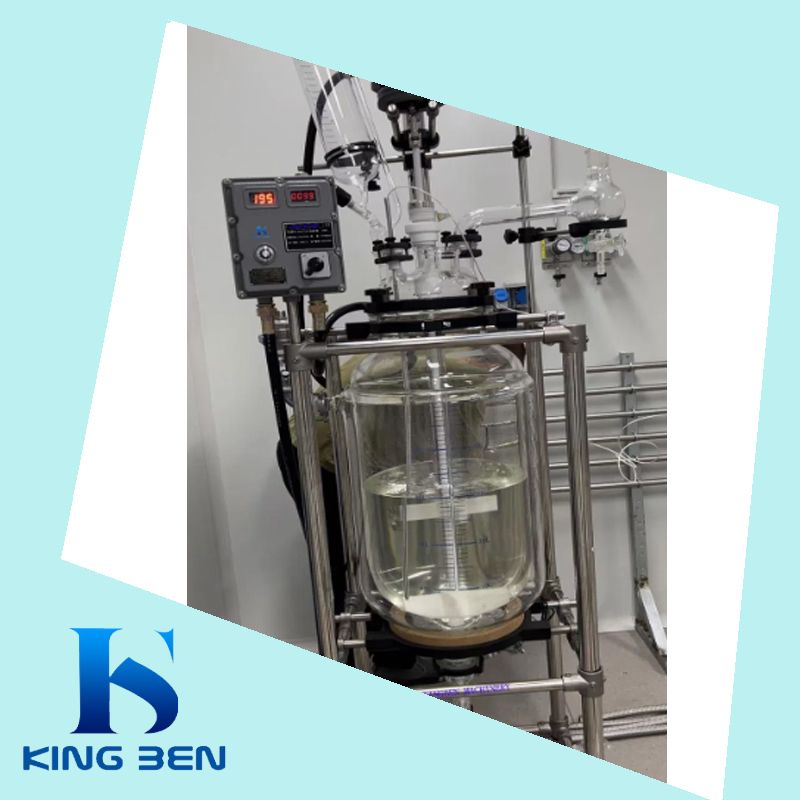

Custom-Made Double Layer High-Pressure Glass Jacketed Reactor for Chemical Laboratory Use

$1,510.00

Description

Introducing our Custom-Built Double Layer High Pressure Glass Jacketed Reactor, designed for precision and efficiency in chemical lab applications. With robust construction and superior thermal control, it ensures optimal reactions. Transform your lab experience—order now!

SKU

0832616712698

Category Chemical Equipment

Tags Batch Chemical Reactor, Chemical Drying Equipment, Chemical Equipment Machinery, Chemical Granulators, China Layer, Continuous Flow Reactor, Double Layer Bag, Double Layer Film, Double Layer Panel, Double Layer Small, Double Layer Steel, High Pressure Machine, Stainless Steel Chemical Reactor, Three Layer, Top 10 Layer, Two Layer

Brand: YANCHENG KING BEN MACHINERY CO., LTD.

Send Inquiry