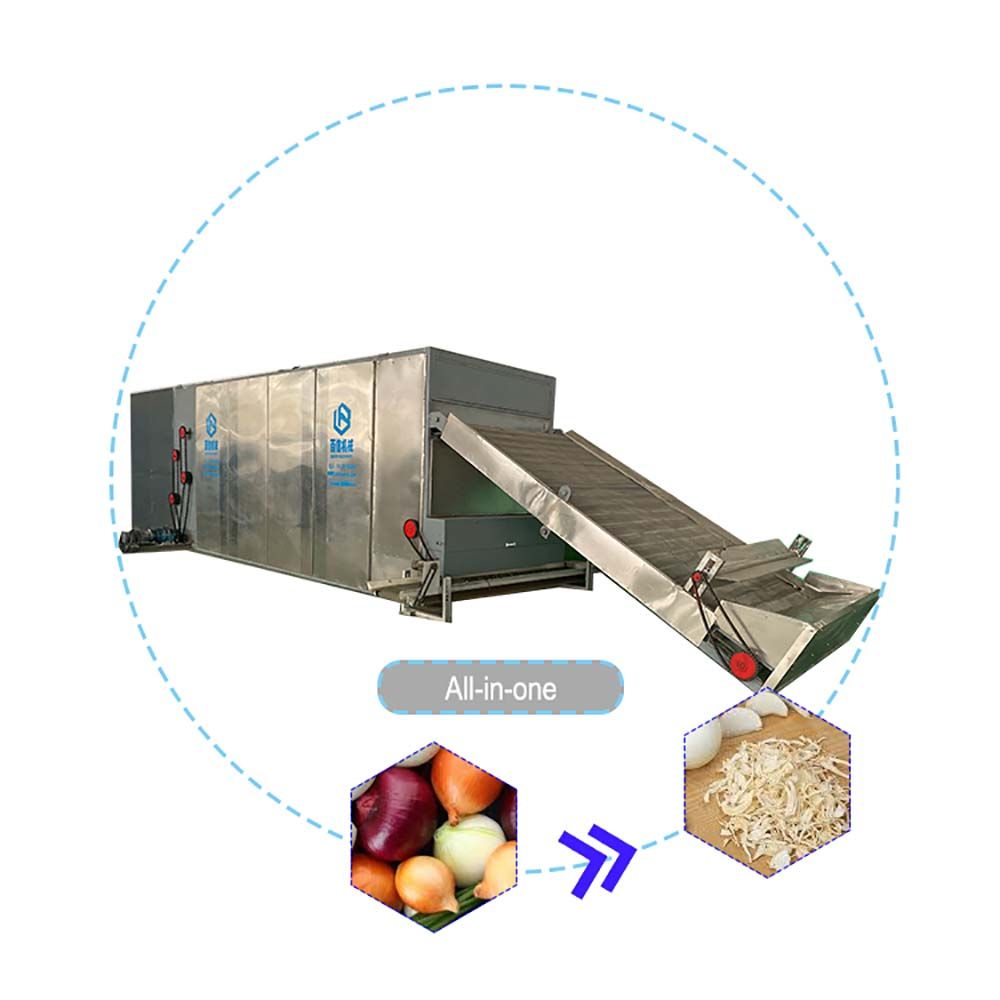

Fully Continuous Pyrolysis Plant for Paint Residue Treatment and Drying with a Daily Capacity of 80 Tons

$880,010.00

Description

Introducing our Fully Continuous Pyrolysis Plant, designed for efficient paint residue treatment and drying. With a daily capacity of 80 tons, this state-of-the-art equipment ensures eco-friendly waste management. Optimize your processes today! Invest in sustainability—buy now!

SKU

9833512561393

Category Chemical Equipment

Tags Chemical Drying Equipment, Chemical Equipment Machinery, Chemical Granulators, China Plant, Continuous Drying Plant, Drying Equipment, Plant Equipment, Plant Machinery, Pyrolysis Equipment, Pyrolysis Plant, Tyre Pyrolysis Plant, Waste Pyrolysis Plant

Brand: Shangqiu Harmony Machinery Manufacturing Co., Ltd.

Send Inquiry