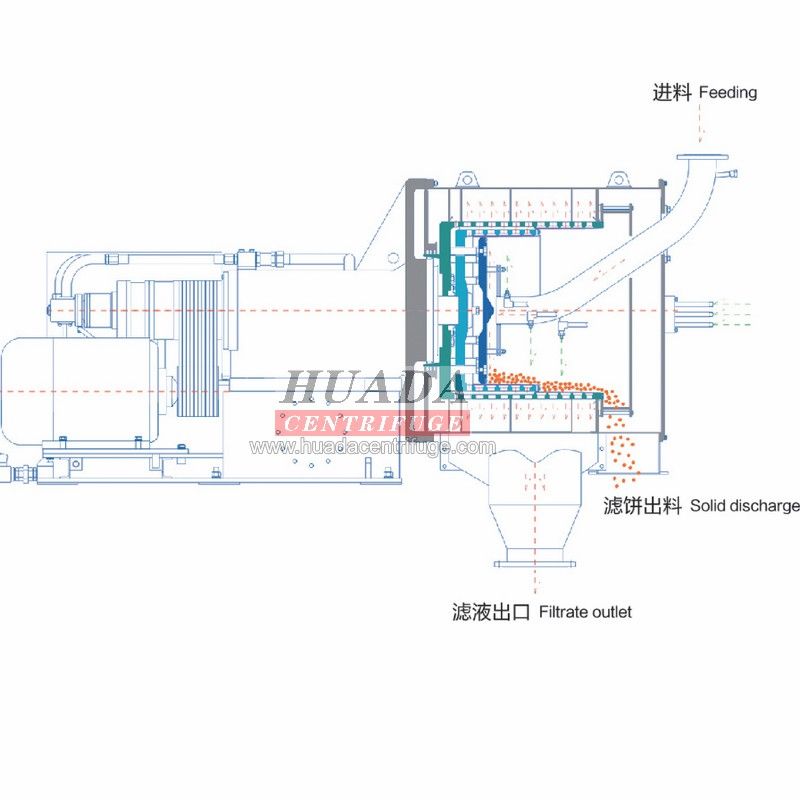

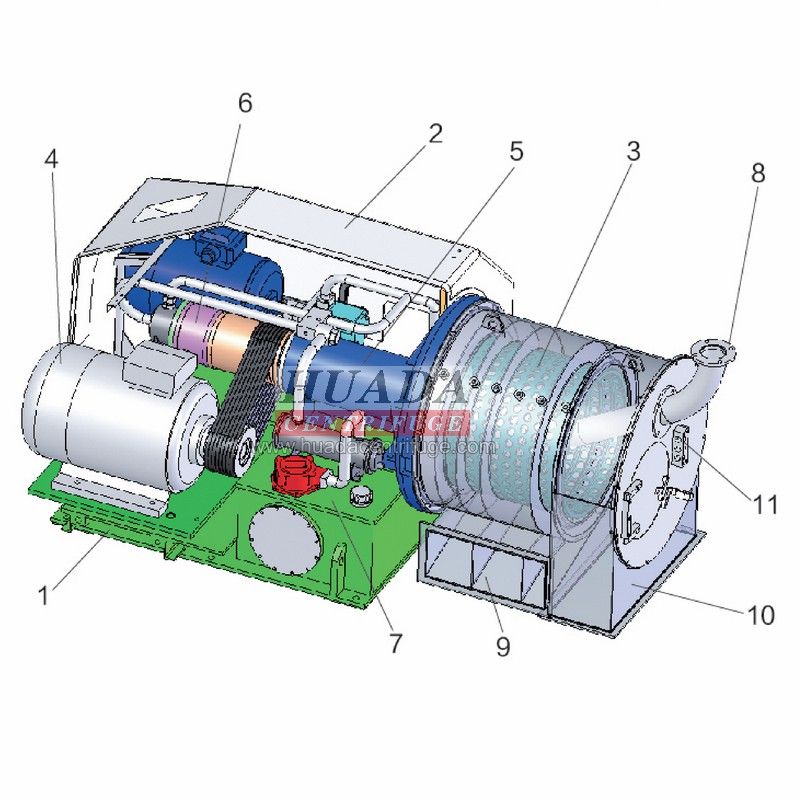

HR Horizontal Two-Stage Pusher Centrifuge for POM Applications

$30,010.00

Description

Introducing our HR Horizontal Two Stages Pusher Centrifuge, designed specifically for efficient POM processing. This advanced equipment ensures optimal separation and minimal downtime. Experience unmatched reliability and performance in your operations. Don’t miss out—elevate your production capabilities today!

SKU

1082185146064

Category Chemical Equipment

Tags Automatic Centrifuge, Automatic Cutting Machine, Automatic Industrial Equipment, Automatic Machine, Centrifuge Industrial, Centrifuge Machines, Centrifuge Separator, Chemical Drying Equipment, Chemical Equipment Machinery, Chemical Granulators, Gold Separation Equipment, Industrial Washing Machine, Recycling Separation Equipment, Sludge Separation Equipment, Used Centrifuge

Brand: Jiangsu Huada Centrifuge Co., Ltd.

Send Inquiry