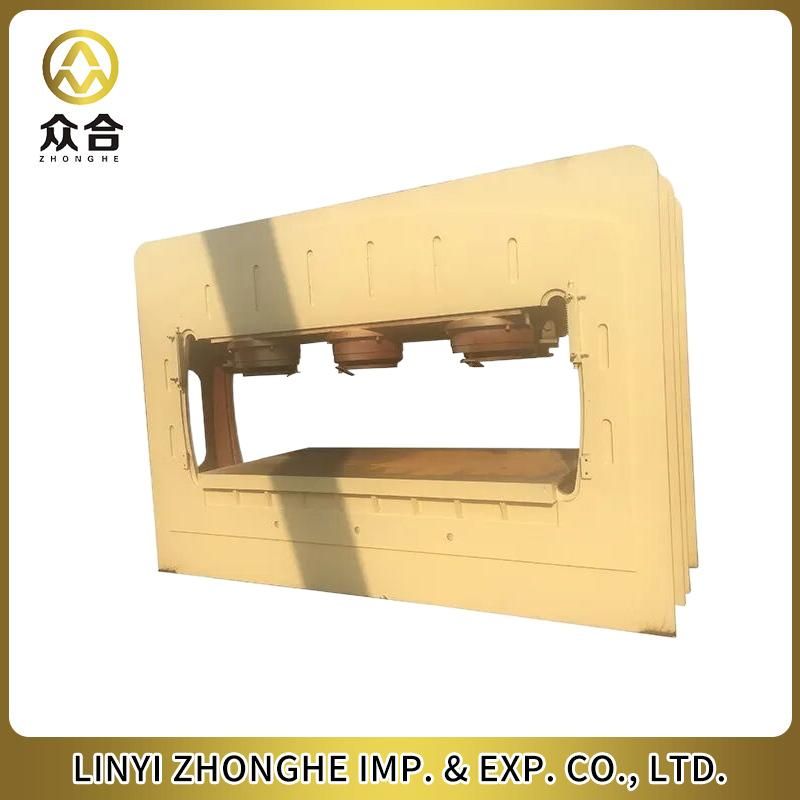

MDF Particle Board Hot Press Machine for Short-Cycle Lamination Line

$41,010.00

Description

Introducing our MDF Particle Board Short Cycle Laminate Hot Press Machine, designed for efficient lamination in your production line. With streamlined operation and exceptional durability, it ensures high-quality finishes for your MDF products. Boost your productivity and elevate your craftsmanship today—order now!

SKU

2393047102646

Category Woodworking Machinery

Tags China Press, High Frequency Wood Based Panel Machine, Hot Machine, Hot Plate Press Machine, Hot Sale Press Machine, Hydraulic Hot Press Machine, Hydraulic Press Machine, Mdf Wood Based Panel Machine, Press Machine, Testing Machine Wood Based Panel Machine, Used Hot Press Machine, Wood Hot Press Machine

Brand: LINYI ZHONGHE IMP. & EXP. CO., LTD.

Send Inquiry